What is the BlueInvest Project Pipeline?

Aerones Engineering

Co-founder and CEO Dainis Kruze and co-founder Janis Putrams. When Dainis was 18 his first company was established. The first successful business was developed together with Aerones co-founder Janis Putrams on 2005, company Intelligent Systems. Both studied together computer programming in University of Latvia and started the business ideas. Currently Intelligent Systems is the largest GPS fleet tracking and management service company in Latvia. Similar business model has been implemented in other co-founding enterprises and businesses like in Advangrid, checkgps.com, tahostar.com. Therefore, model has approved itself as successful and also will be implemented in Aerones.

The wind turbine market is growing rapidly and will remain a key renewable energy option in the coming decades.

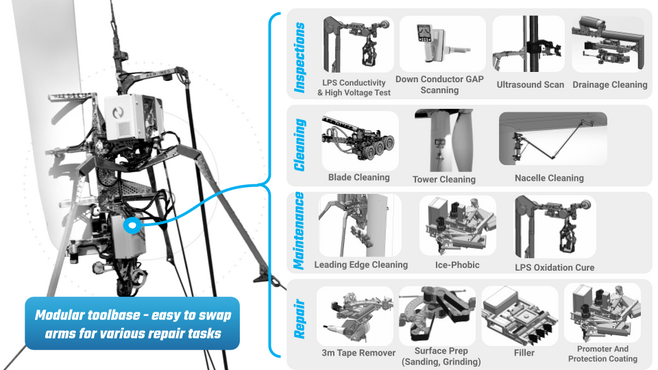

It is encouraged by following: the growing global energy demand; decline of average installed costs for offshore wind turbines; and the zero-pollution emission goal legitimated in EU Green Deal. Currently offshore wind turbine maintenance services are provided with rope access. The turbine is stopped for a few days and all this time vessels are involved. As a result O&M service is time and resource expensive, and produces significant amounts of CO2 emissions. The aim of the project is to develop robotic offshore wind turbine maintenance system up to level TRL8. Aerones has developed robotic onshore wind turbine maintenance system up to the commercialization stage. Together with a consortium and in-kind contributors within the project offshore robotic systems’ prototype will be developed, and set of testings will be made. Development will be protected by at least 3 IP applications. As a result an offshore wind turbine maintenance service will become less resource intensive. It won’t require rope access and will be manageable remotely, therefore raising a significant security level for workers. The maintenance service will be provided 3 to 6 times faster than the current solutions; therefore, turbine will be stopped for less time and income loss will be reduced significantly. The service also will be less expensive therefore inspections will be available more often. Those early stage inspections will prevent wind turbine blades from progressing to serious damage where produced energy drops by 30% or turbine even stops. Therefore efficiency of the wind turbine will increase and its lifetime will prolong. Technology has a significant impact on reduction of CO2 (up to 6 400 000 t of CO2 emissions yearly), reduction of marine pollution (up to 37% in 5 years) while the blue economy is thriving, therefore getting closer to goals set in an international strategies.

4x less downtime for wind turbine blade maintenance works, 2x CO2 reduction, 30-40% cost savings by more efficient energy production and blade lifetime extension

.png)

What is the BlueInvest Project Pipeline?

The BlueInvest Project Pipeline is a database and showcase of projects, scale-ups and SMEs who are driving innovation and sustainability in the Blue Economy.

The projects featured are innovative, scalable and sustainable business ventures from traditional and emerging sectors of the maritime economy.

The aim is to facilitate connections between projects and investors, helping innovative ventures gain visibility and access to funding opportunities.

Want to be featured?

Login to the BlueInvest community & Submit your project

Selection criteria

- Your company is EU-based or from an eligible sea basin region (Georgia, Turkey, Ukraine, Moldova, Montenegro, Albania, Bosnia-Herzegovina, North Macedonia, Serbia, Israel, Egypt, Tunisia, Algeria, Morocco, Lebanon, Syria, Libya, Mauritania, United Kingdom, or Norway)

- Your project TRL is 4 or higher

- Your project sector is in one of the 10 blue economy sectors identified for this initiative

- Your solution has a clear sustainable impact on the blue economy

- Your project is looking for investment